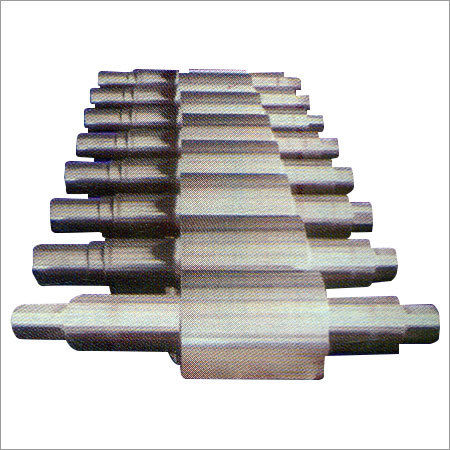

Induction Hardened Rolls

Price 30000 INR/ Piece

Induction Hardened Rolls Specification

- Product Type

- Rolls

- General Use

- Straightening Sheet Rolls

- Material

- Steel Alloy

- Type

- Drilling, Milling, Turning

- Surface Treatment

- Chrome Plating

- Feature

- High Performance, Simple Control, Stable Operation, High Efficiency

Induction Hardened Rolls Trade Information

- Minimum Order Quantity

- 4 Pieces

- FOB Port

- Kolkata

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash Against Delivery (CAD), Cheque

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 2 Months

- Main Domestic Market

- All India

About Induction Hardened Rolls

Specification

|

Size |

450 dia ,length 4000 mm |

|

Tolerance |

High |

|

Shape |

round |

|

Automation Grade |

Semi-Automatic |

|

Finishing |

As per drawing |

|

Diameter |

As per customer drawings |

|

Surface Treatment |

Induction hardening |

|

Weight |

Finish weight 3000 kgs |

|

Hardness |

55 to 65 HRC as per requirements |

|

Packaging Type |

Wooden box |

|

Usage/Application |

Rolling mill,straightening mill,Hi mill |

|

Country of Origin |

Made in India |

|

Material |

Steel |

|

Uses |

Industrial |

FAQs of Induction Hardened Rolls:

Q: What are Induction Hardened Rolls used for?

A: They are primarily used for straightening sheet rolls and in applications like rolling mills, straightening mills, and Hi mills.Q: What is the hardness range of these rolls?

A: The hardness is customizable, ranging from 55 to 65 HRC, based on specific requirements.Q: What material are the rolls made from?

A: These rolls are made from high-quality steel alloy.Q: How are the rolls packaged?

A: Induction Hardened Rolls are securely packaged in wooden boxes.Q: What is the size of these rolls?

A: The rolls are 450 dia and 4000 mm in length.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Hardend Rolls & Shafts Category

Rolling Mill Rolls

Minimum Order Quantity : 4 Pieces

Type : Turning, Other

Feature : High Performance, High Efficiency, Simple Control

Material : Steel Alloy

Product Type : Roller and shaft

Work Roll and Backup Roll

Price 20000 - 200000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Drilling, Other, Turning

Feature : Simple Control, High Performance, High Efficiency

Material : Steel Alloy

Product Type : Rolls

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free